InstructionFlue gasoline desulfurization and denitration technology is a boiler flue fuel purification technology carried out to the chemical industry of multi nitrogen oxide and sulfur oxide generation. nitrogen oxides and sulfur oxides are one of the principal assets of air pollutants. consequently, the application of this era has many advantages for ambient air purification.

Contacta ahora

IntroduceFlue gasoline desulfurization and denitration era is a boiler flue gas purification technology implemented to the chemical enterprise of multi nitrogen oxide and sulfur oxide era. nitrogen oxides and sulfur oxides are one of the predominant resources of air pollution. therefore, the utility of this era has many benefits for ambient air purification.

Contacta ahora

Basic InstructionAccording to executive director Sun Deshan, the international trade business of Guoshun group has become one of the "troikas" in parallel with the main environmental protection industry of air pollution control and the green fabricated steel structure construction industry. In the international market, it mainly undertakes steel structure engineering projects and flue gas treatment projects, especially steel structure engineering projects.

Contacta ahora

InstructionFlue gas desulfurization and denitration technology is a boiler flue gas purification technology applied to the chemical industry of multi nitrogen oxide and sulfur oxide generation. Nitrogen oxides and sulfur oxides are one of the main sources of air pollution. Therefore, the application of this technology has many benefits for ambient air purification.

Contacta ahora

InstructionFlue gas desulfurization and denitration generation is a boiler flue gasoline purification technology completed to the chemical industry of multi nitrogen oxide and sulfur oxide technology. nitrogen oxides and sulfur oxides are one of the foremost property of air pollutants. therefore, the software of this era has many benefits for ambient air purification.

Contacta ahora

IntroduceFlue gas desulfurization and denitration technology is a boiler flue gas purification technology applied to the chemical industry of multi nitrogen oxide and sulfur oxide generation. Nitrogen oxides and sulfur oxides are one of the main sources of air pollution. Therefore, the application of this technology has many benefits for ambient air purification.

Contacta ahora

InstructionCentral heating, iron and metal organizations and thermal electricity flowers in urban wintry weather are large-scale coal-fired production, which has grow to be the supply of air pollution. in recent years, all localities have followed active environmental safety policies.

Contacta ahora

InstructionImportant heating, iron and metal companies and thermal power plants in city iciness are large-scale coal-fired production, which has grow to be the supply of air pollutants. in latest years, all localities have adopted active environmental protection guidelines.

Contacta ahora

InstructionCentral heating, iron and steel enterprises and thermal power plants in urban winter are large-scale coal-fired production, which has become the source of air pollution. In recent years, all localities have adopted active environmental protection policies.

Contacta ahora

InstructionImportant heating, iron and metal businesses and thermal strength flowers in town iciness are huge-scale coal-fired manufacturing, which has grow to be the supply of air pollutants. in state-of-the-art years, all localities have adopted energetic environmental protection pointers.

Contacta ahora

A steel truss for houses began to appear in the last 4-5 years. Previously, conventional steel material had been widely used, but for industrial construction. A conventional steel structure is known for strong and has high durability. This structure allows the building to be made with a wide span. The steel used for construction is generally I-shaped and tied each other using the dynabolt system. The original steel material is black. The color of steel sold on the market is generally given further treatment.

Contacta ahora

InstructionPrimary heating, iron and metallic groups and thermal strength plant life in city wintry weather are large-scale coal-fired manufacturing, which has come to be the supply of air pollutants. in latest years, all localities have followed lively environmental protection guidelines.

Contacta ahora

Basic InstructionThe steel components are painted with primer coating immediately after the shot blasting treatment and the interval between which is less than 30 seconds guaranteeing the strong adhesion film. The thickness of primer can be adjusted with different components to satisfy the anti corrosion requirement. The high quantity of surface treatment and strong primer adhesion together with normative fireproof coating guarantee the high efficient and long-term anti corrosion.Steel structure pre-treatmentSteel structure fabricationPacking and shipping

Contacta ahora

Basic InstructionThe steel components are painted with primer coating immediately after the shot blasting treatment and the interval between which is less than 30 seconds guaranteeing the strong adhesion film. The thickness of primer can be adjusted with different components to satisfy the anti corrosion requirement. The high quantity of surface treatment and strong primer adhesion together with normative fireproof coating guarantee the high efficient and long-term anti corrosion.Steel structure pre-treatmentSteel structure fabricationPacking and shipping

Contacta ahora

Basic InstructionThe metal components are painted with primer coating immediately after the shot blasting treatment and the c program languageperiod between that is much less than 30 seconds making sure the robust adhesion film. the thickness of primer may be adjusted with specific additives to meet the anti corrosion requirement. the high quantity of floor treatment and sturdy primer adhesion collectively with normative fireproof coating guarantee the high efficient and lengthy-time period anti corrosion.Steel structure pre-treatmentSteel structure fabricationPacking and shipping

Contacta ahora

IntroducePlate heat exchanger has the characteristics of excessive warm temperature alternate ordinary performance, small warmth loss, compact and light-weight shape, small ground region, massive software and extended provider life.

Contacta ahora

Stainless steel heat exchanger is a kind of heat exchanger made of stainless steel. It has very good oxidation resistance, safety and health, and is widely used in food, medicine, heating, domestic water, air conditioning return water and other fields. According to the data of the heat exchange equipment promotion center, the stainless steel heat exchanger has better heat transfer effect and longer service life than the traditional carbon steel heat exchanger.Stainless steel heat exchanger has been widely used in many fields at present.

Contacta ahora

IntroducePlate heat exchanger has the characteristics of excessive warmness change performance, small heat loss, compact and light-weight shape, small ground vicinity, wide software and lengthy service lifestyles.

Contacta ahora

IntroducePlate warmness exchanger has the characteristics of excessive warmth change overall performance, small warmth loss, compact and light-weight form, small floor vicinity, huge software and prolonged service lifestyles.

Contacta ahora

Wear resistant steel plate refers to special plate products specially used under large area wear conditions. The commonly used wear-resistant steel plate is a plate product which is made by overlaying a certain thickness of alloy wear-resistant layer with high hardness and excellent wear resistance on the surface of ordinary low carbon steel or low alloy steel with good toughness and plasticity. In addition, there are cast wear-resistant steel plates and alloy quenched wear-resistant steel plates.

Contacta ahora

Falling film evaporation is to add the feed liquid from the upper tube box of the heating chamber of the falling film evaporator, evenly distribute it to each heat exchange tube through the liquid distribution and film-forming device, and form a uniform film to flow from top to bottom under the action of gravity, vacuum induction and air flow. During the flow process, it is heated and vaporized by the shell side heating medium. The generated steam and liquid phase enter the separation chamber of the evaporator together.

Contacta ahora

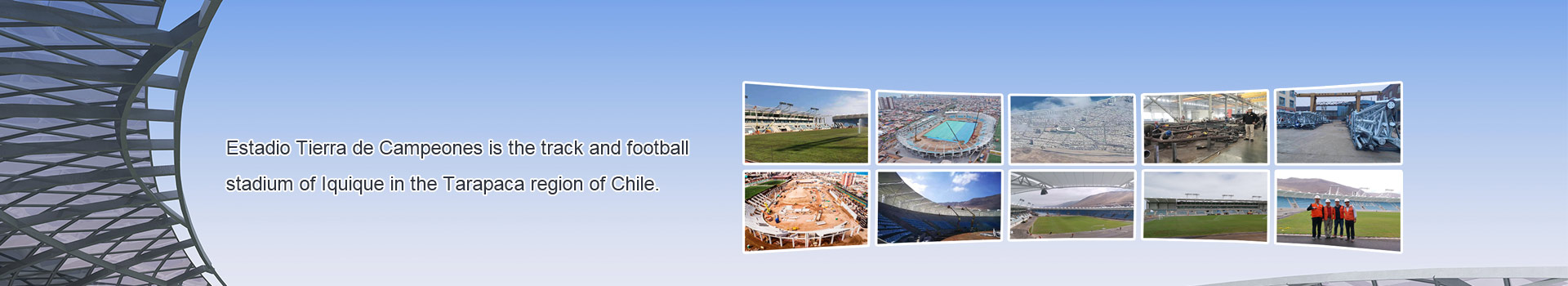

Basic InstructionThe complete process supervision and inspection of the assignment changed into completed with the aid of the international well-known bureau veritas. the layout, production and full assembly offerings of guoshun organization had been evaluated as "very glad" by using the owner icafal ingenier í a y constructi ó n s.a. (the 6th largest standard contractor in chile and rated because the countrywide champion of chilean creation sustainable development business enterprise through the chilean residence of representatives).Site Display

Contacta ahora

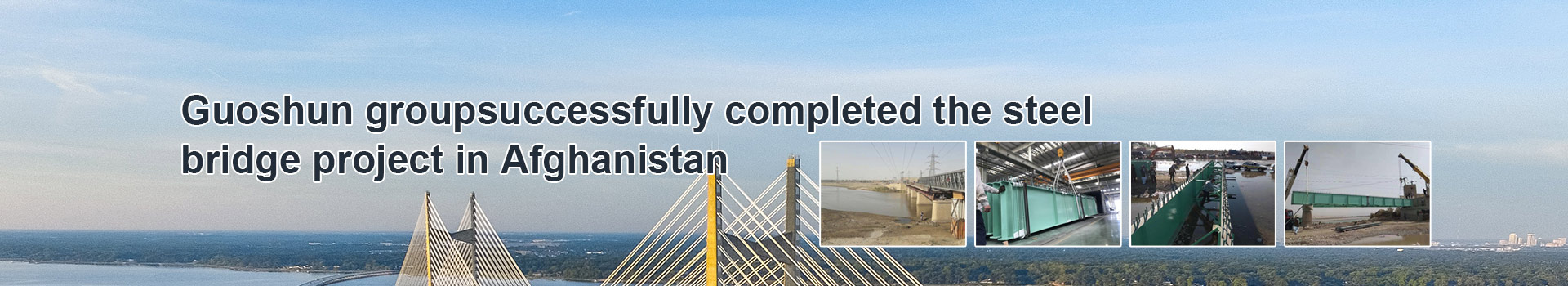

Basic InstructionRonald lwakatare, leader executive of tanzania's fast transit authority, said that they had acquired $148.1 million for phase iii and $99.9 million for phase iv. "the price range acquired will make contributions to the real construction of brt infrastructure, and the authorities might be accountable for compensating folks that will be tormented by the assignment," he said.the bridge has a total period of 111 meters and a span of five meters,40-4 meters of it were blown up for the duration of the preventing.

Contacta ahora

IntroductionSteel bridge is a bridge whose main bearing structure is steel, i.e. steel structure bridge and steel bridge. Fabricated steel bridges have been widely used all over the world. The original fabricated steel bridge was designed by British engineer Donald Bailey at the beginning of World War II in 1938. The main design concept is to assemble the fabricated steel bridge with the least kinds of unit components, which can bear various loads and different spans, and only need to be transported by general medium-sized trucks. In special cases, it can be built entirely by manpower

Contacta ahora